Choosing the Right Optical Fibre Diameter Analyser for Your Fibre Optic Manufacturing Needs

Choosing the Right Optical Fibre Diameter Analyser for Your Fibre Optic Manufacturing Needs

Blog Article

How an Optical Fibre Diameter Analyser Enhances Quality Assurance in Fibre Production

The combination of an Optical Fibre Diameter Analyser into Fibre manufacturing processes stands for a significant improvement in top quality control approaches. By using real-time, specific measurements of Fibre sizes, this innovation resolves the vital demand for uniformity in manufacturing requirements.

Value of Fibre Diameter Measurement

Precise measurement of Fibre Diameter is essential in the field of optical Fibre technology, as it directly influences the performance and dependability of Fibre optic systems. The Diameter of an optical Fibre influences its light-carrying capacity, depletion, and total transmission performance. Accuracy in determining Fibre Diameter guarantees that the optical homes are preserved within specified tolerances, which is vital for optimum signal honesty.

Variants in Fibre Diameter can result in enhanced losses due to scattering and modal diffusion, affecting the high quality of data transmission. In high-speed interaction systems, such disparities can lead to considerable deterioration of signal high quality, leading to information mistakes and decreased efficiency. In addition, consistent Fibre Diameter is important for compatibility with adapters and splicing modern technologies, which are indispensable components of Fibre optic networks.

Quality control procedures in Fibre manufacturing heavily rely upon precise Diameter dimensions to ensure conformity with industry standards. By applying robust dimension methods, suppliers can improve item dependability, minimize waste, and enhance total system performance. Therefore, the importance of Fibre Diameter measurement can not be overemphasized, as it functions as a foundation in the advancement of optical Fibre modern technology and its applications in modern communication networks.

How the Analyser Works

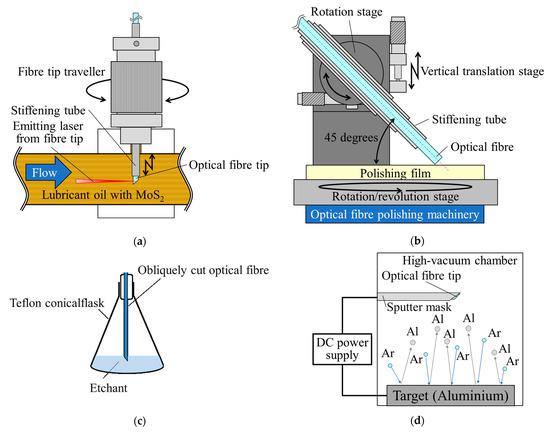

The reliable measurement of Fibre Diameter counts on sophisticated logical techniques that make certain precision and dependability in optical Fibre production (optical fibre diameter analyser). The Optical Fibre Diameter Analyser uses a combination of laser innovation and progressed photo processing formulas to accurately evaluate the Diameter of fibers as they are produced

At first, a laser beam of light is routed at the moving Fibre, producing a cross-sectional darkness. The analyser captures this shadow utilizing high-resolution electronic cameras positioned strategically along the assembly line. The caught pictures are then processed in real-time to figure out the Fibre's Diameter with outstanding precision.

The system uses advanced algorithms that make up numerous variables, including variants in light strength and ecological problems, to enhance measurement integrity. It can discover minute modifications in Diameter, such as variations that might occur during the manufacturing process.

Furthermore, the analyser is capable of dealing with several fibers simultaneously, enhancing throughput without endangering accuracy. By providing immediate feedback on the Diameter, the Optical Fibre Diameter Analyser plays an essential role in keeping strict top quality control requirements, guaranteeing that the last item fulfills industry specifications and consumer needs.

Benefits of Real-Time Monitoring

While traditional approaches of keeping track of Fibre Diameter commonly involve lengthy post-production checks, real-time monitoring substantially enhances the effectiveness and quality of optical Fibre production. optical fibre diameter analyser. This aggressive strategy allows suppliers to recognize inconsistencies in Fibre Diameter as they occur, instead of waiting up until production is full to assess quality

By constantly determining the Diameter throughout manufacturing, suppliers can make certain that the fibres meet rigid specifications, resulting in decreased irregularity and boosted uniformity. Real-time tracking additionally allows instant corrective activities to be taken, lessening waste and protecting against malfunctioning fibres from going into the supply chain.

Moreover, this innovation promotes boosted data collection and evaluation, giving insights into manufacturing fads and prospective locations for renovation. Such data-driven decision-making empowers manufacturers to maximize processes and preserve high criteria of quality assurance.

On top of that, real-time surveillance fosters a society of constant renovation within the manufacturing setting. Workers are much more engaged when they can see the impact of their operate in real-time, bring about increased liability and a commitment to quality. Generally, the application of real-time surveillance systems in optical Fibre production converts to superior product quality and boosted client contentment.

Influence On Manufacturing Performance

Applying optical Fibre Diameter analysers substantially improves manufacturing efficiency by enhancing the manufacturing process. These devices promote continual tracking of Fibre Diameter, allowing suppliers to spot deviations in real-time. By identifying inconsistencies promptly, assembly line can be adjusted rapidly, minimizing downtime and reducing the chance of creating faulty products.

In addition, the assimilation of these analysers into the production operations enables far better resource allocation. With exact Diameter measurements, drivers can optimize product usage, guaranteeing that resources are not lost on mistaken fibres. This accuracy likewise adds to much less remodel and look at here now junk, inevitably lowering manufacturing expenses.

The automation supplied by optical Fibre Diameter analysers minimizes reliance on hand-operated evaluations, which are vulnerable and frequently taxing to imp source human mistake. Therefore, employees can concentrate on even more critical tasks, improving overall performance.

Furthermore, the data produced from these analysers can educate process renovations and promote better decision-making. By assessing trends in Fibre Diameter variants, producers can apply proactive procedures to boost manufacturing techniques and preserve consistent high quality. In recap, optical Fibre Diameter analysers play a critical function in enhancing manufacturing efficiency, causing greater top quality output and enhanced earnings.

Instance Studies and Success Stories

Across different markets, study highlight the transformative impact of optical Fibre Diameter analysers on manufacturing processes. One prominent example is a leading telecommunications business that dealt with obstacles with irregular Fibre sizes, bring about raised being rejected rates. By integrating an optical Fibre Diameter analyser, the business accomplished real-time tracking of Fibre dimensions, resulting in a 30% reduction in problems and significant price financial savings.

Additionally, a study organization focusing on sophisticated materials used optical Fibre Diameter analysers to fine-tune their speculative processes. The analyser's capacity to offer detailed insights right into Fibre uniformity enabled the growth of innovative products with improved efficiency characteristics.

These success tales underscore the necessary role of optical Fibre Diameter analysers in enhancing high quality control, boosting production effectiveness, and driving innovation across varied industries.

Final Thought

In verdict, the Optical Fibre Diameter Analyser plays a crucial duty in boosting top quality control within Fibre manufacturing. As shown via numerous instance researches, the analyser confirms essential for attaining premium item top quality in Fibre manufacturing.

The application of optical Fibre Diameter analysers allowed for rigid quality control, making certain that the created fibers met exacting sector standards.In verdict, the Optical Fibre Diameter Analyser plays a crucial function in boosting quality control within Fibre production.

Report this page